Features

RosettaCNC can handle up to 6 continuously interpolated axes. Each axis has its own parameterization. Accurate acceleration control is performed during interpolation.

RosettaCNC Board implements, like the most advanced CNCs, the Look-ahead function that allows you to increase tool speed while running Gcode with small segments. The depth of the look-ahead implemented is 2000 points.

When "CONTINUOS" work mode is selected, RosettaCNC Board moves the axes to try to keep the tool at constant speed. When you are in the presence of an edge, it is rounded up with a quadratic Bezier type trajectory. The amount of rounding can be set with a dedicated parameter.

Fast, robust, isolated. These are the characteristics of the 100Mbit Ethernet connection used for connection to the PC.

Thanks to the ethernet port that manages two simultaneous connections, it is possible to control CNC machine through the RosettaCNC software and at the same time another communication acts as supervising or sending work file.

Thanks to a peer-to-peer communication infrastructure, it is possible to control workmanship comfortably from home or to be informed about certain events such as alarm, tool change, end processing, etc. (in development)

Dual etherneth communication channel, sending work from office PCs, SDK to develop interfacing with management software, etc. All of this makes RosettaCNC the right solution for who want to integrate the product into a scenario that meets the Industry 4.0 needs.

Each movement is verified by the trajectory generator to ensure the right acceleration value. This is useful for avoiding mechanical stresses but also to avoid losing any steps when you run STEPPER motors. All movements and conditions are verified: JOG, HOMING, PAUSE, REPAIR PROCESSING, FAST SHIFT OVERIDE, STOP PROCESSING, ecc...

The new software is distributed either by publishing a new installation package or by using an automatic update system. Distributed software is always stable. Automatic updating ensures that new features are deployed quickly and practically.

STEP / DIR command outputs are generated by a powerful FPGA that allows to reach 1MHz operating frequencies (with 50% duty cycle stable), making it possible to use both stepper drives and servo drive.

The development team is always at work to develop new features and make RosettaCNC a complete product

The feed is controllable by an external MPG. Its digital signal allows accurate control of the value avoiding variations by humidity, wear, temperature, offset of electrical circuitry, etc …

The RosettaCNC software interface is customizable with a custom logo. The software already supports this feature and there is no need for an agreement with the development team.

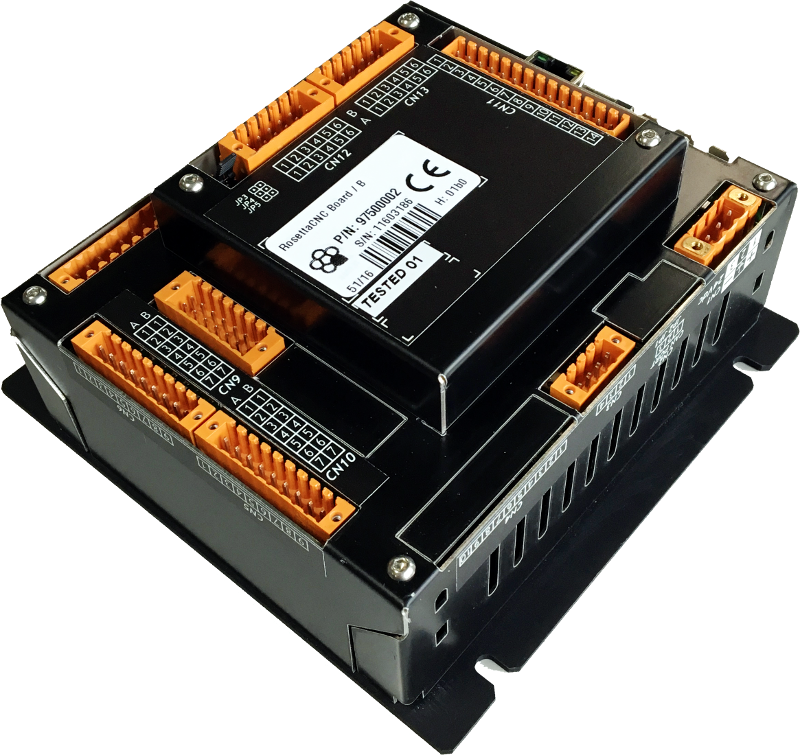

Features

RosettaCNC can handle up to 4 continuously interpolated axes. Each axis has its own parameterization. Accurate acceleration control is performed during interpolation.

RosettaCNC Board implements, like the most advanced CNCs, the Look-ahead function that allows you to increase tool speed while running Gcode with small segments. The depth of the look-ahead implemented is 2000 points.

When “CONTINUOS” work mode is selected, RosettaCNC Board moves the axes to try to keep the tool at constant speed. When you are in the presence of an edge, it is rounded up with a quadratic Bezier type trajectory. The amount of rounding can be set with a dedicated parameter.

Fast, robust, isolated. These are the characteristics of the 100Mbit Ethernet connection used for connection to the PC.

Thanks to the ethernet port that manages two simultaneous connections, it is possible to control CNC machine through the RosettaCNC software and at the same time another communication acts as supervising or sending work file.

Thanks to a peer-to-peer communication infrastructure, it is possible to control workmanship comfortably from home or to be informed about certain events such as alarm, tool change, end processing, etc. (in development)

Dual etherneth communication channel, sending work from office PCs, SDK to develop interfacing with management software, etc. All of this makes RosettaCNC the right solution for who want to integrate the product into a scenario that meets the Industry 4.0 needs.

Each movement is verified by the trajectory generator to ensure the right acceleration value. This is useful for avoiding mechanical stresses but also to avoid losing any steps when you run STEPPER motors. All movements and conditions are verified: JOG, HOMING, PAUSE, REPAIR PROCESSING, FAST SHIFT OVERIDE, STOP PROCESSING, ecc...

The new software is distributed either by publishing a new installation package or by using an automatic update system. Distributed software is always stable. Automatic updating ensures that new features are deployed quickly and practically.

STEP / DIR command outputs are generated by a powerful FPGA that allows to reach 300KHz operating frequencies (with 50% duty cycle stable), making it possible to use both stepper drives and servo drive.

The development team is always at work to develop new features and make RosettaCNC a complete product

The feed is controllable by an external MPG. Its digital signal allows accurate control of the value avoiding variations by humidity, wear, temperature, offset of electrical circuitry, etc …

The RosettaCNC software interface is customizable with a custom logo. The software already supports this feature and there is no need for an agreement with the development team.